Across North America, drinking water treatment plants have to keep trihalomethanes (THMs) — a potential carcinogen — below strict limits.

However, if they don’t have sophisticated gas chromatography equipment and trained specialists on site, plants must rely on commercial labs to test their samples. That means waiting up to a week to get results, which can delay action to address high TMH levels. Considering that each test costs somewhere in the range of $120 to $150, frequent testing gets expensive.

Imagine the difference it would make to get results in an hour, for just two dollars per test. That’s the promise of new technology from A.U.G. Signals Ltd. (AUG), a Toronto-based leader in sensor technology.

Faster, more effective feedback lets plants optimize performance

Over the course of the past two years, AUG has been working with Professor Ronald Hofmann, a leading expert in drinking water treatment at the University of Toronto, and the drinking water facility in the municipality of Smiths Falls, to test and refine their prototype. The project is funded through SOWC’s Advancing Water Technologies (AWT) program, which is supported by the Federal Economic Development Agency for Southern Ontario (FedDev Ontario).

Normally, drinking water plants add coagulants to the incoming water to remove organic material before disinfecting it with chlorine. However, each summer a boom in zebra mussels at the Smiths Falls site forces the plant to chlorinate the raw, incoming water to prevent mussels from clogging up the intake. And when chlorine reacts with organic material, it can create THMs.

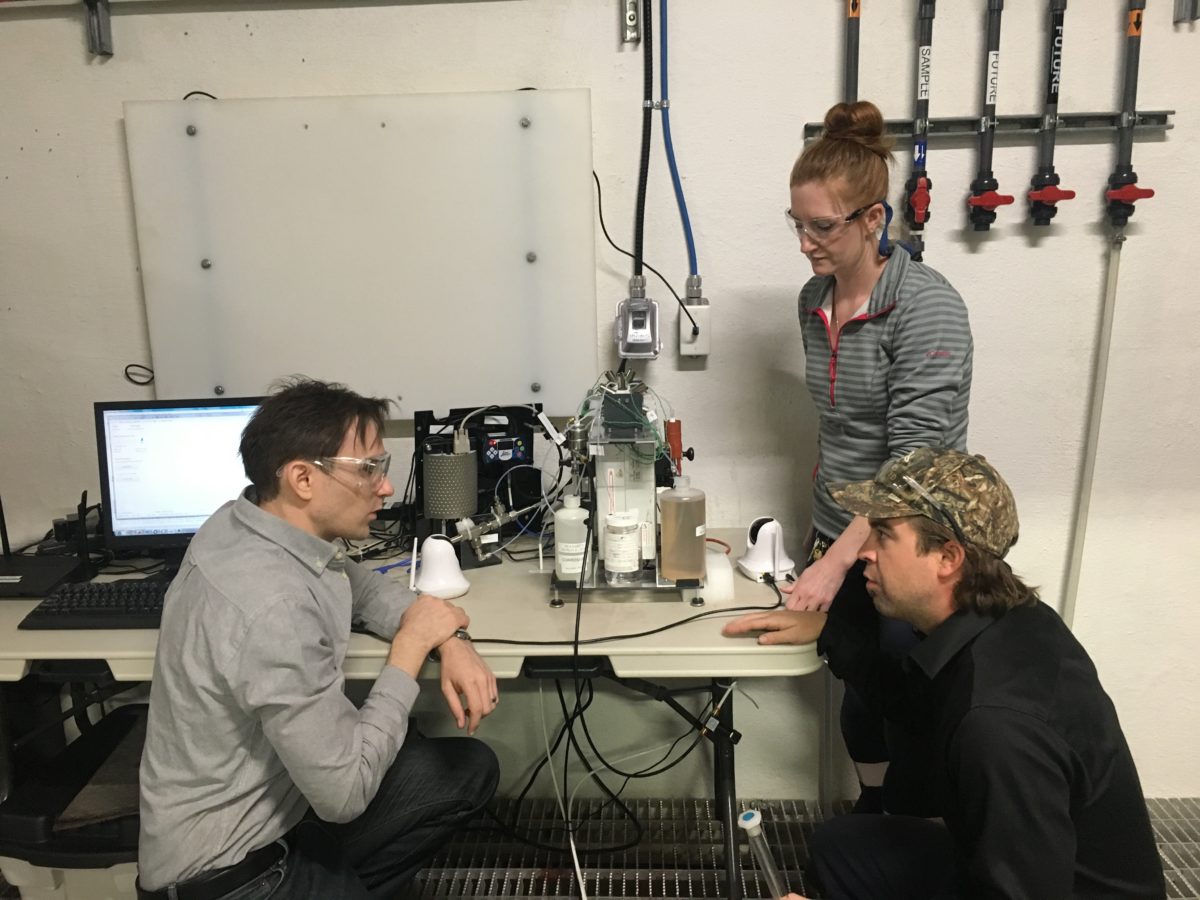

AUG’s system uses chemical reagents that change colour when they react with THMs, measuring those subtle changes with a photonic spectrometer. The results are ready in just 45 minutes. Thanks to that speedy feedback, plant managers can fine-tune chlorine, pH and coagulant levels, and keep zebra mussels in check without exceeding THM standards.

Although the plant still needs to conduct quarterly or monthly manual sampling and laboratory tests to comply with provincial regulations, AUG’s analyzer provides a valuable early-warning system when THM levels creep up.

AWT project leads to validation, refinements and jobs

The AWT program was established to connect Ontario companies with academic researchers, helping promising technologies get to market sooner. And that’s exactly what it has achieved, according to Cindy Dongxin Hu, AUG’s senior project manager.

First, the AWT-funded collaboration allowed AUG to validate its analyzer. In Professor Hofmann’s civil engineering lab at the University of Toronto, water samples from Smiths Falls were tested using standard gas chromatography procedures. Those same samples were also tested using AUG’s analyzer in Smiths Falls, yielding impressively similar results. “That’s a huge, huge asset to the company,” says Hu.

At the same time, the project allowed AUG to refine its prototype, based on feedback from the Smiths Falls operators.

AUG’s principal chemical engineer Eric Morris lists all the improvements they’ve made as a result, transforming a lab-bench prototype into market-ready equipment. Morris uses the example of syringe pumps. His team has reduced the number required from six to two, simplifying operations. Another pump has become more powerful, reliable and faster, by slashing the analysis time from 2.5 hours to 45 minutes.

Hu chimes in, describing how the company improved the mixing process to cut back the volume of reagents required. They’ve also scaled down the size of the photonic detection components, lowering the cost of the unit. Finally, they’ve made the overall design smaller and sleeker and tweaked the software interface. According to Hu, those kinds of major improvements couldn’t have been done nearly as fast without AWT funding.

Meanwhile, the project has created new professional jobs in the company. For example, a senior engineer was brought on board at the beginning to advance the design of the analyzer. Now, AUG is adding an entry-level mechatronics engineer to focus on micro-fluidics.

Opening up a world of commercial opportunities

When the AWT initiative wraps up this fall, AUG plans to launch a few large-scale pilot tests prior to commercial launch. Once they begin selling their analyzer, Hu and Morris foresee big uptake, especially in smaller municipalities and First Nations communities where high THM levels are a common concern.

“In most of the developed world, I think there’s going to be a market for this,” says Morris. And with no other companies offering comparable technology, AUG’s analyzer is bound to make a global splash. “This [is] the next rising star in the company’s product line,” Hu predicts.