Around the world, wastewater regulations are getting stricter. But meeting them isn’t always easy. Remote and rural municipalities lack the tax base to support needed upgrades and the higher operating costs that often accompany them. Attracting and retaining the staff to run complex systems can also be challenging. Meanwhile, urban areas often lack space to expand their facilities.

Bishop Water offers a simple solution. The Renfrew, Ontario company has developed the BioCord™ Reactor. These compact cubes provide an affordable, low-energy way to boost wastewater treatment capacity and nutrient-removal performance without expanding a facility’s footprint.

BioCord Reactors are installed directly into a wastewater lagoon to improve nutrient removal. This design helps keeps capital costs low since additional tanks and related equipment are not required.

Inside each unit, thousands of polymer-fibre loops create a massive surface area where microbes can attach and multiply — and get busy breaking down organic material. Bishop CEO Kevin Bossy calls it a condominium for bacteria.

Because the technology is modular, managers can choose how many or how few units they need for their lagoon or treatment basins. Meanwhile, the self-regulating, self-cleaning systems require minimal oversight and maintenance. “We can retrofit your existing infrastructure with our system and increase your capacity with little change to the operator’s day-to-day work,” Bossy explains.

Providing the proof to gain market traction

Bishop Water has come a long way since the company’s launch in 2008. And Bossy believes they couldn’t have gotten this far, this fast, without support from OWC.

After some initial trials at a nearby wastewater treatment plant in Eganville, they were ready to scale up their testing. OWC had the connections they needed, helping Bossy broker a deal with the town of Dundalk, 90 minutes northwest of Toronto.

The growing community faced a familiar dilemma. Before they could build more homes, they had to increase their sewage treatment capacity. However, they lacked enough ratepayers to pay for infrastructure expansions. BioCord Reactors were just the ticket. OWC helped navigate the necessary environmental assessments and approvals, and in 2016, Bishop Water added 10 of their units to Dundalk’s sewage lagoon.

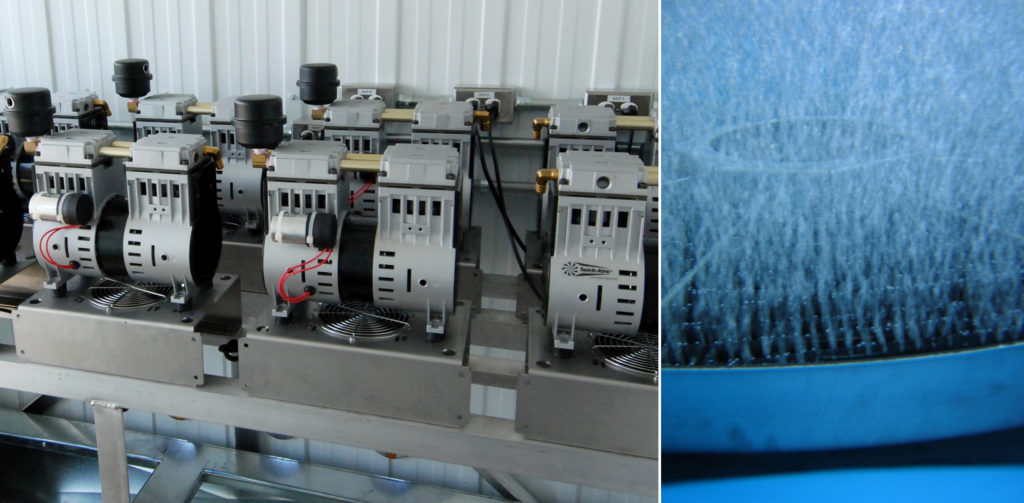

BioCord is like a condominium for bacteria that provides a massive surface area on which nutrient reducing biofilm (right) can thrive. The system is self-regulating, self-cleaning and requires little operator oversight to achieve its performance targets.

The pilot provided real-world data that proved the solution was effective. But the company wanted to take the technology even further. Once again, OWC stepped in with crucial support, connecting the company to university researchers and funding the work through two Advancing Water Technologies (AWT) grants.

Taking the tech to the next level

A collaboration with Dr. George Nakhla at Western University verified the BioCord Reactor’s effectiveness in challenging cold-weather conditions and improved the system’s performance. A second collaboration with Western’s Dr. Martha Dagnew helped optimize aeration.

Traditional treatment plants rely on massive, costly blowers to supply the bacteria with the oxygen they need to break down organic material. However, they consume a lot of energy, making up a significant part of municipal budgets and greenhouse gas emissions.

In contrast, BioCord Reactors use a fine-bubble aeration system that runs on compressors, which are affordable, easy to maintain and require very little electricity. The partnership with Dagnew proved that the system could significantly reduce target nutrients while dramatically slashing operating costs and carbon emissions.

Each BioCord Reactor is equipped with a micro-bubble aeration system powered by a low-energy compressor, which enables high oxygen transfer to the biofilm for a fraction of the capital and operating costs of a typical blower-powered lagoon aeration system.

The two AWT projects provided an impressive sheaf of evidence to convince potential customers the technology provided significant advantages over alternatives. They also led to further research collaborations with Dagnew supported by Mitacs, the Ontario Centres of Excellence and the Natural Sciences and Engineering Research Council. Those opportunities allowed Bishop Water to do the modelling they needed to scale up, as well as investigate how effectively the BioCord Reactor can break down emerging contaminants like perfluoroalkyl substances (PFAS).

Supporting growth and innovation

But the AWT benefits didn’t stop there. The projects also provided a pipeline of talent for the growing company. To date, a third of Bishop Water’s staff members have come via research collaborations. “That OWC/university partnership is definitely a key for attracting and retaining quality employees,” says Bossy.

For Dagnew, the projects give her students an opportunity to understand industry needs, develop hard and soft skills, and see tangible impacts of their work. “It shows them the big picture,” she says.

BioCord Reactors are being evaluated by several communities and industrial facilities worldwide and were recently installed at the growing rural community of Limoges, Ontario, just east of Ottawa. Last fall, they added 60 units to their wastewater lagoons, more than doubling treatment capacity for less than half the cost of the next closest bidder — without expanding the lagoon’s footprint.

The system will enable the wastewater lagoon to handle higher nutrient loading, reduce retention times and remove more ammonia, even in winter. As a result, Limoges will be able to continuously discharge treated effluent year-round.

Two cells of 30 BioCord Reactors were installed at the Limoges WWTF. Baffle curtains around the reactors form a raceway that maximizes contact time and enables the most intensive arrangement of the reactors.

Bishop Water has also exported systems to customers in Australia and New Zealand, and Bossy expects to add Europe and Mexico to that list soon. Meanwhile, the company has introduced other products to their lineup: the Bishop Solids Management Solution and a rare earth coagulant called ClariPhos™ that removes phosphorus more effectively than conventional coagulants, and reduces sludge volumes.

“What we’ve tried to create are simple, low-cost, low-energy-based systems that will allow any community to meet the regulatory requirements that they are being asked to meet,” Bossy explains. “That’s kind of our ethos.”

It’s an approach that has earned awards from the Water Environment Association of Ontario, Ontario Public Works, and the Ministry of Environment and Climate Change. Meanwhile, the company won a 2020 Water’s Next Award for their full-scale project in Limoges.

According to Bossy, OWC played a crucial role in Bishop Water’s success. “They give you a safe space to test and validate your technology,” he says.

Dagnew also applauds OWC for bringing together Ontario’s water professionals and helping turn the province’s companies into world leaders. “My colleagues in the water industry really value what AWT provided,” she says. Now, she adds, we need ongoing investments in innovation to keep Ontario positioned at the global forefront.

Want to learn more about Bishop Water’s BioCord™ Reactor?

Registration is NOW OPEN for Bishop Water’s webinar where they will introduce their affordable, low-energy technology, BioCord™ Reactor, for boosting wastewater treatment capacity and nutrient-removal performance. The webinar will also include applications and case studies of their technology. Registration is FREE for everyone!

Date: Tuesday, September 28th, 12:00 – 1:00 pm