Going with the flow is an adage Forward Water Technologies won’t argue with.

The Mississauga, Ontario company has developed a new forward osmosis technology that uses engineered “switchable salts” to purify wastewater. It’s a low-energy process for bulk cleanup of industrial wastewater streams and is aimed at alleviating the global demand for fresh water and reducing the volume of wastewater requiring treatment and disposal.

“Taking water out of the water table just doesn’t make sense,” says Howie Honeyman, Chief Executive of Forward Water, who notes the importance of water preservation as global water shortages become more prominent and industries continue to rely on massive amounts of fresh water for their operations.

Alongside researchers at the University of Toronto (UofT) and supported by the Southern Ontario Water Consortium’s Advancing Water Technologies (AWT) program, the company is working to accurately predict the economics of its forward osmosis technology at large commercial scale.

“The central project objective is to generate a global process model which can be used to validate and optimize our process economics,” Mr. Honeyman says.

Using data from Forward Water’s mini pilot plant in Mississauga, UofT Professor Vladimiros Papangelakis and his team are working with the company on two main project components — fundamentals and industrial application, which involves setting up a chemical process optimization software model.

“We will be using fundamental information that we develop at UofT to provide value and for the parameters needed to run the software and predict the operations of the mini pilot plant,” says Papangelakis. “By having a reliable model, which is fine-tuned and calibrated on real data, we will be able to expand the range of investigation and optimize the process.”

The key objective is arriving at the optimum conditions that allow the process to run successfully using a minimum energy expenditure, according to the UofT chemical engineering professor.

Forward Water, founded by GreenCentre Canada, is initially targeting the industrial and oil-and-gas production sectors, both of which can generate a significant amount of wastewater that must be transported and disposed of at a high cost.

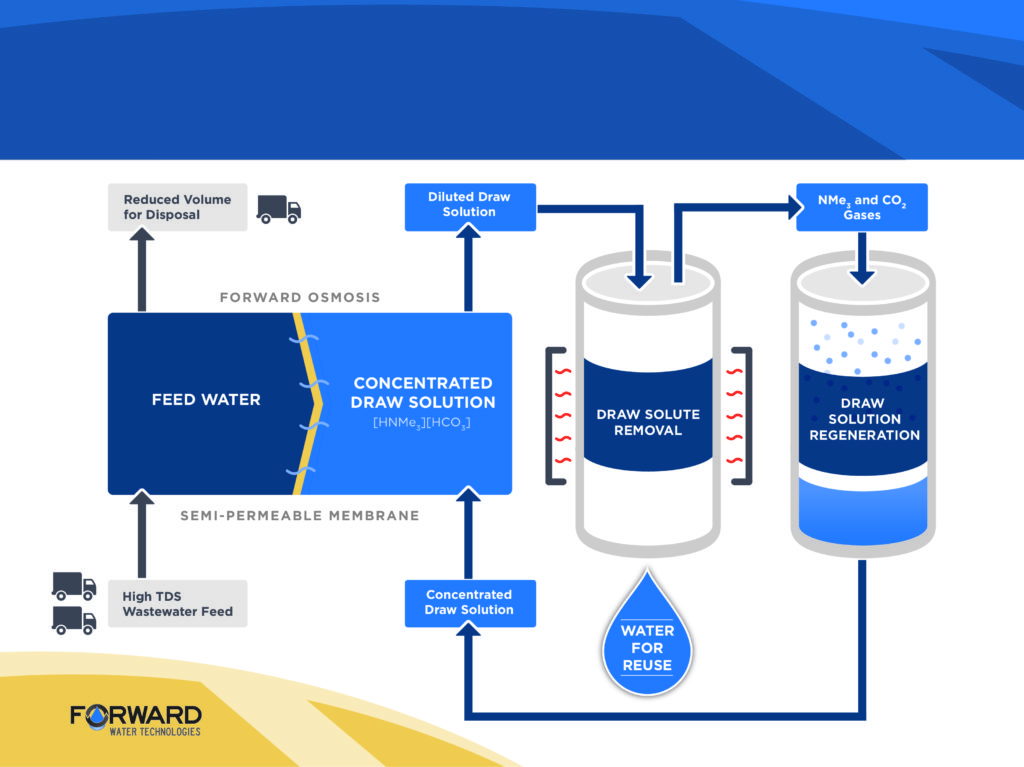

The company’s forward osmosis technology, a relatively new water-treatment process involving the spontaneous transfer of water through a semi-permeable membrane, is aimed at allowing the economical treatment of saline water while providing a fresh-water stream that can be recycled into operations.

Forward Water Technologies’ Block Flow. Copyright: Forward Water Technologies

“This process is essentially complementing and extending the reverse-osmosis standard in the industry,” says Papangelakis.

Rather than relying on energy-intensive pumps to force water through porous membranes in a reverse-osmosis process, Forward Water takes advantage of the natural direction of water flow — from an area of low salt concentration to one of high salt concentration — by using a draw solution containing engineered switchable salts invented at Queen’s University. Once the contaminated water filters into the briny solution containing the engineered salts, a small amount of heat is introduced to switch the salts to gases. Those gases bubble out of the solution leaving clean water behind to be reused in operations, while the gases are captured and reused in the draw solution.

The amount of heat needed for the success of Forward Water’s technology is already available in most industrial operations in the form of low-grade waste heat.

“Our process is low-energy enough that instead of wasting that heat and throwing it away, we can use it,” Honeyman says.

“Two things have become very clear to me,” says Honeyman. “You have to intertwine sustainability and economic viability. They’re no longer separate ideas.”

As part of the AWT funding program, UofT researchers are working to calculate the optimum amount of energy required to be applied in Forward Water’s process. A winning case for the technology will be a process that meets the same water-cleanness standard of reverse osmosis processes with a lower energy expenditure, says Papangelakis.

“Once the reliable model identifies this optimum, this will allow Forward Water to prove unequivocally that the process is really operating under the minimum energy expenditure, meets the performance specifications and even can be scaled up from the mini pilot size to a full plant size,” says Papangelakis.

While it’s early days in the year-long AWT-funded project, both Papangelakis and Honeyman are encouraged by the progress so far.

“It’s coming very quickly up to speed and because there’s such a high degree of communication, we’ve been able to get things going very quickly,” Honeyman says of working with Papangelakis and his team.

Papangelakis agrees that the amount of communication and cooperation offered by Forward Water has been valuable in advancing the project.

“It has been an excellent partnership,” he says, noting Forward Water’s willingness to share information, provide training and offer full access to the mini pilot plant located at the Xerox Research Centre. “This is an outstanding training camp for the students,” he adds. He believes the project, which he says has already generated a great deal of new information in terms of the chemistry and the behaviours of the chemicals, has the potential to make a breakthrough in the relatively new field of forward osmosis in wastewater treatment.

That belief is also helping fuel Honeyman’s drive to push the project ahead.

“Having someone come along and validate what you believe, it’s really pretty spectacular,” Honeyman says.