When companies in the water sector want an R&D partner at the University of Toronto, they turn to the Institute for Water Innovation (IWI). Established in 2015, the research collective focuses on solving big water issues — from managing tailing ponds in the oil sands to designing wetlands that can remove stubborn contaminants.

As manager of the IWI, Mandeep Singh Rayat serves as a kind of concierge, linking industrial partners with researchers in the Faculty of Applied Science & Engineering and forging academic collaborations within the faculty itself.

“My role is to act as a facilitator and a matchmaker,” he says. “I really see myself as a connector.” And by bringing together interdisciplinary teams, he’s helping IWI to tackle major water-related challenges.

Made-to-order microbiomes

Those challenges include accelerating the shift to a circular economy by viewing wastewater as a resource. Traditionally, the goal of treatment plants has been to clean sewage enough to safely release it into lakes and rivers. Some plants have begun capturing the methane from anaerobic digestion and burning it to generate electricity.

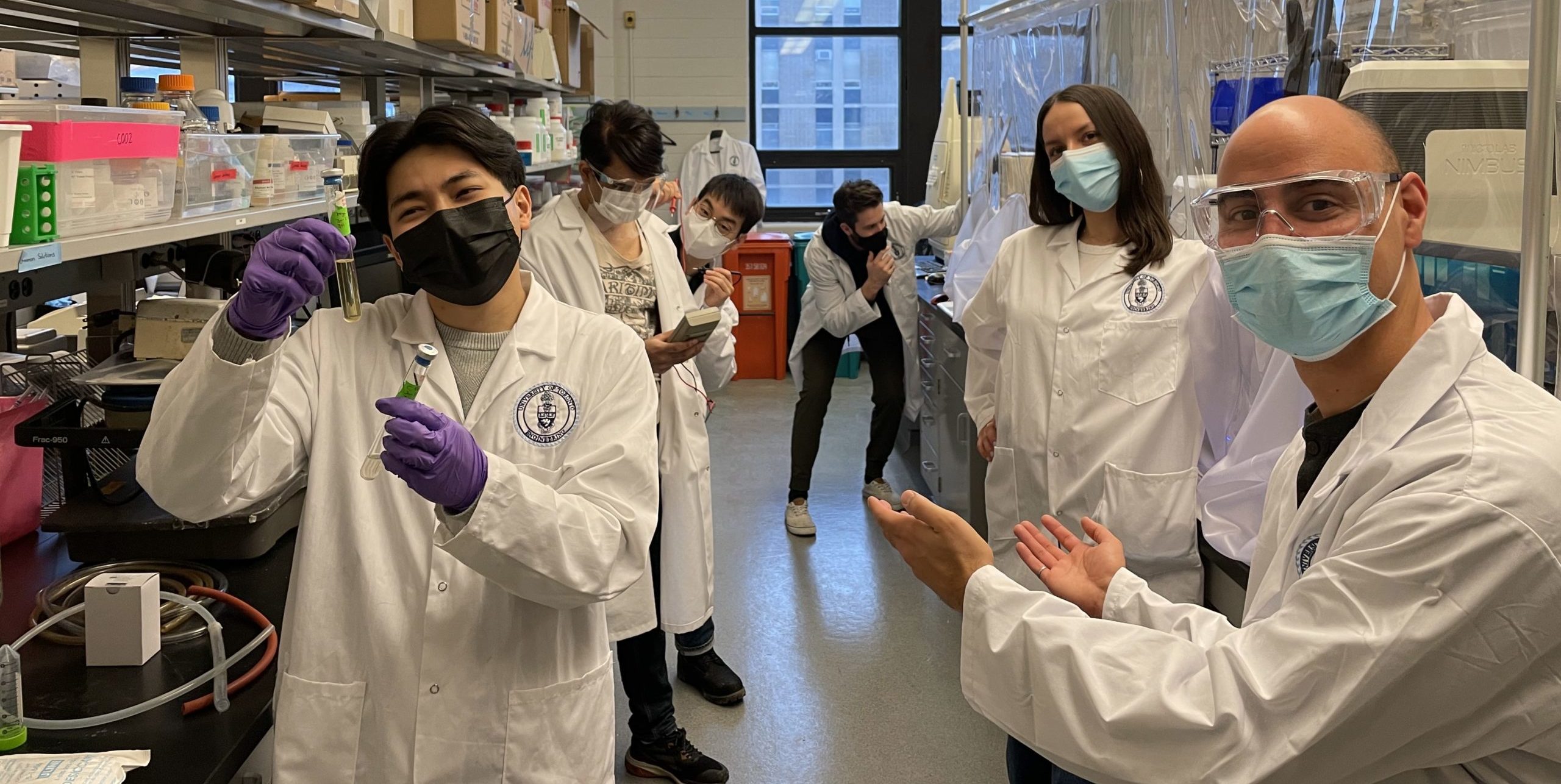

But IWI researcher Christopher Lawson believes that’s just the beginning. He points to many high-value substances that can be produced from the so-called “wastewater” before it is discharged. Today, he and his team at the university’s Microbiome Engineering Lab are designing microbial communities to transform sewage into all sorts of valuable industrial chemicals.

For example, by leveraging novel anaerobic bacteria, they’re able to turn wastewater sludge and food waste into medium-chain fatty acids — a common ingredient in animal feed that typically comes from the environmentally destructive process of producing palm kernel oil.

They’re also using synthetic biology tools to tweak these bacteria so they can create biofuels like alcohols and alkanes. Tweak them again and you can generate other valuable chemicals like adipic acids, an important component in making nylon. “[We’re] mixing and matching the right microbes to get the functions we want. When necessary, were also introducing new functions using synthetic biology,” says Lawson.

Because wastewater treatment plants are already designed to harness the power of bacteria, manipulating the microbiology doesn’t require any serious infrastructure changes. However, getting bacteria to produce a particular chemical is one thing. Extracting and purifying that chemical is another.

“The chemical industry doesn’t want some dilute chemical in water,” explains Lawson. “They want a high-purity product.”

Membranes to the rescue

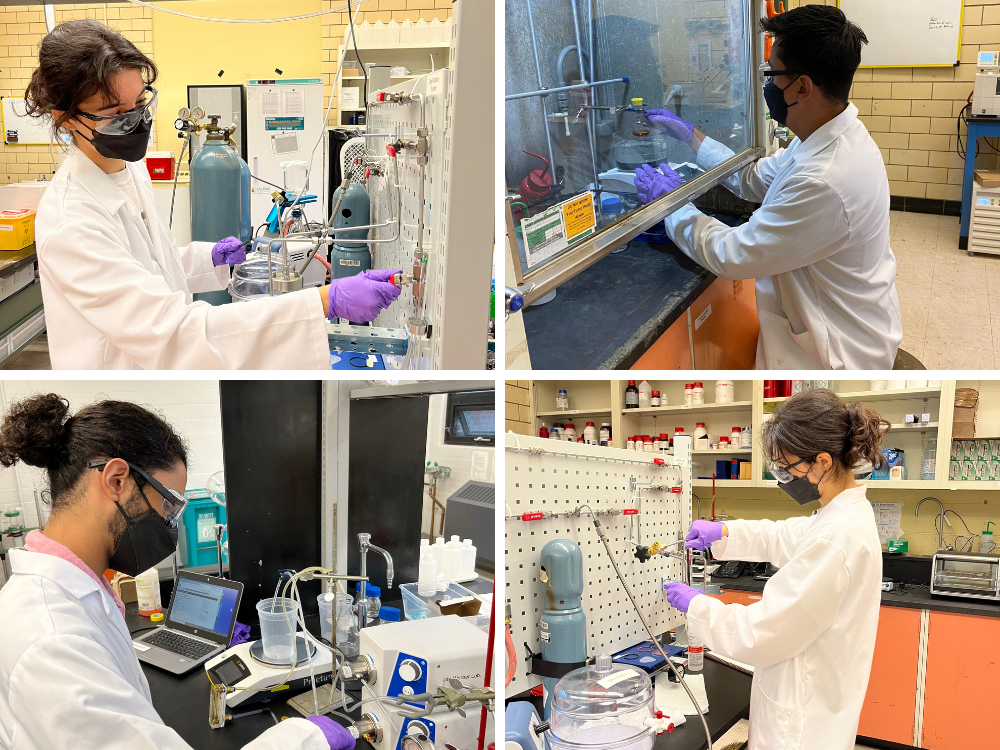

To solve that problem, Lawson teamed up with fellow IWI researcher Jay Werber. At the university’s Advanced Membranes Lab, Werber is using hydrophobic polymers to create a membrane capable of removing fatty acids from wastewater. “Separation of these things are challenging, but for me membranes seem like an obvious way to do it,” he says.

But that’s only one use for the ultra-thin films that his team is developing to let targeted molecules pass through, while keeping out others.

Another important application is desalination. Today, reverse osmosis membranes are widely used to remove salt and minerals from seawater. However, the technology has limits, typically only working in water with relatively neutral pH levels and modest amounts of dissolved solids.

To overcome those limitations, Werber is experimenting with different nanomaterials to construct membranes that could desalinate water under more challenging conditions. These could potentially replace the energy-intensive evaporative processes currently used to treat wastewater in the pulp and paper sector.

His team is also developing highly selective ion-separation membranes. If they’re successful, this could help mining operations remove problematic contaminants like cobalt from their effluent, so that it can be safely discharged into the environment. “Our goal is to try to make those technologies more robust,” he says.

For Werber, a huge motivation for using membranes is the possibility to cut energy use and eliminate the need for chemical solvents. “I always view sustainability issues as the seminal challenge of my generation — and probably my kids’ generation,” he says.

A team effort

Rayat says internal collaborations like this are incredibly fruitful. But it doesn’t stop there. He also sees opportunities to partner with other institutions in the province. And that’s an area where he believes the Ontario Water Consortium (OWC) has a big role to play.

“We’re familiar with what’s happening at U of T, but we don’t really know what’s happening at other universities,” he says. “The consortium is a great way to bring similar institutes together.”

And, of course, moving from the lab to real-world applications requires industrial partners. Werber hopes to work with water engineering firms and utilities to scale up his membranes. Meanwhile, Lawson aims to have his resource-recovering microbes ready to pilot at wastewater treatment plants within three to five years.

“Water research is not a one-person show,” says Lawson. “It requires lots of different collaboration and expertise.” And that’s where both IWI and OWC can help play matchmaker.