Across the Athabasca oil sands, energy companies are wrestling with a sticky question: what to do with the tailings they produce. The byproduct of mining bitumen, tailings are a mixture of water, fine clay particles and other suspended solids that get pumped into large ponds where they are left to settle — a process that can take decades or longer.

To speed up that process, the industry has tried many different approaches. For example, adding a flocculent encourages the clay particles to clump together and settle more quickly. Meanwhile, centrifugation spins tailings at high speeds to separate the solid and liquid components. However, these methods can only draw out a certain amount of water, leaving behind a paste that’s more molasses than terra firma.

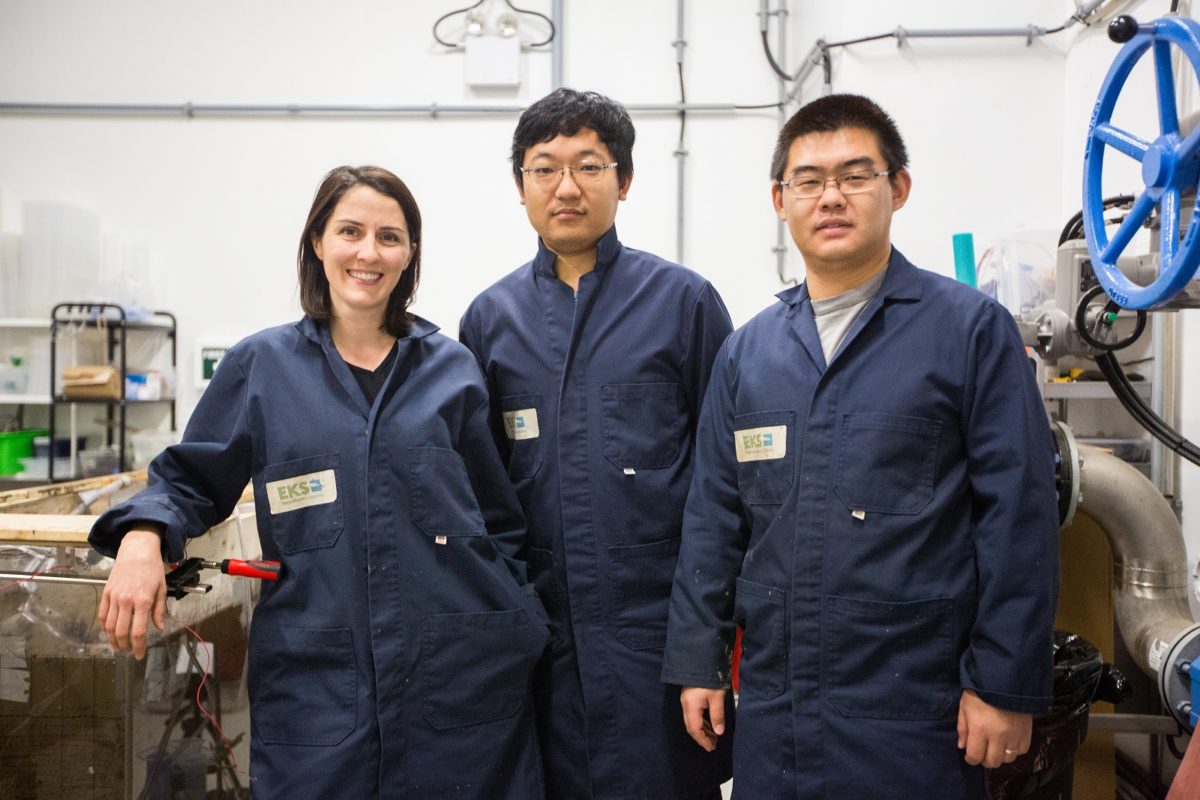

“They are producing massive quantities of these tailings, and a viable solution for rapidly dewatering them is not available right now,” says Dr. Clare Armstrong. “This is a very difficult-to-deal-with substance.” As the manager of research and development for ElectroKinetic Solutions (EKS), Armstrong and her colleagues believe they’ve found a better way to tackle the issue.

Electrifying results

EKS’s electrokinetic dewatering system sends an electrical current through the tailings soup — a current that draws the clay particles to an anode via electrophoresis and squeezes them together into compact solids. At the same time, electro-osmosis draws water toward a corresponding cathode, effectively and efficiently separating the two primary components.

To get the science behind their new technology right, EKS has collaborated with Dr. Julie Shang. The professor of environmental engineering at Western University has been studying electrokinetic applications since the early 1990s, becoming the go-to expert in this field. “It’s hard to do research on electrokinetics and not encounter research undertaken by Julie,” says Armstrong.

Shang’s lab experiments provided EKS with lots of promising results, demonstrating how electrokinetics could offer a reliable, energy-efficient and cost-competitive approach to dewatering. Depending on an oil sands company’s needs, the technology can transform tailings into anything from a pumpable paste to solid bricks that can be used in reclamation projects to restore disturbed land. Meanwhile, the separated water is clear and clean enough to be reused as industrial process water.

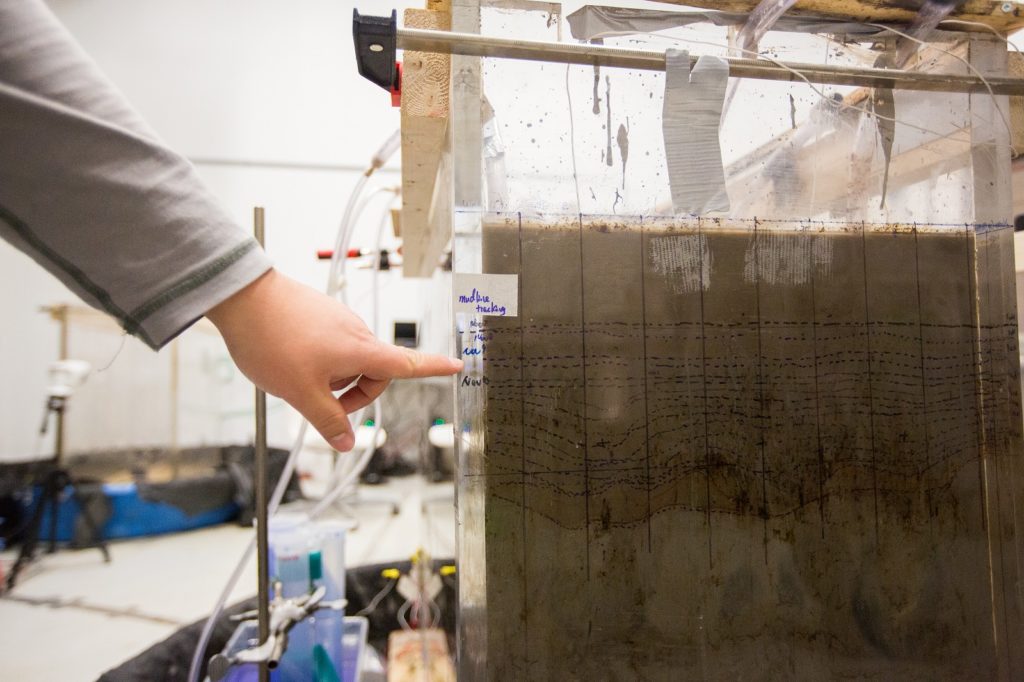

However, working with 20x15x10-centimetre test cells in a lab is a very different proposition from dewatering massive tailings ponds in the oil sands. To address a slew of practical engineering questions for in-field application, EKS needed to scale up their design. To help make that happen, they turned to the Southern Ontario Water Consortium’s Advancing Water Technologies (AWT) program — a program that helps Ontario companies bring new technologies to market.

Test cell at the SOWC London Wastewater Facility demonstrating the potential of EKS’s electrokinetic dewatering system. Copyright: SOWC

Dewatering dream team

AWT funding enabled EKS to work with two researchers from Shang’s lab: post-doctoral fellow Jack Guo and former graduate student Chang Liu. Guo and Liu brought exactly the kind of electrokinetic skills and know-how that EKS was looking for. “You need people with specialized skills to run this lab program,” says Armstrong. “It turned out to be just the perfect fit.”

The team also needed more elbowroom to perform larger-scale tests. For that, they took advantage of SOWC’s demonstration facility, located in a wastewater treatment plant in London, Ontario.

There, the EKS team is fine-tuning the technology for oil sands applications, experimenting with the key chemical and physical reactions to optimize the design of their system. Working with metre-long aquariums filled with tailings materials shipped all the way from Alberta, the group is testing different spacing of the cathodes and anodes to maximize dewatering efficiency, to improve energy efficiency and more.

“The grant itself has been immensely helpful,” says Armstrong. “[It’s] a stepping stone to get us out of an academic lab and into a real, field application.”

Shang agrees. For her protégés, it’s an opportunity to work in their field of expertise and gain valuable career-building experience. Meanwhile, seeing her work applied to real-world problems is extremely rewarding. “That’s the ultimate purpose of our research,” she says. “It’s really a win-win situation to work on this project.”

Changing the game

Today, EKS is preparing to launch a field demonstration and is looking for oil sands producers to test their system on a commercial scale. If those tests are successful, EKS’s technology could literally change the face of Alberta, transforming vast expanses of tailings ponds into solid land suitable for vegetation and wildlife. And because the process allows oil sands companies to reuse water from tailings, it promises to reduce the pressure on the Athabasca River watershed.

Meanwhile, working at the London facility prompted Armstrong to start thinking about how their technology could also be applied to municipal wastewater. She and Shang are now working on a second AWT funded project, with Dr. Bassim Abbassi at the University of Guelph, this time looking at how the electrokinetic system could not only help dewater sewage sludge but also clarify raw sewage, eliminating the need for flocculation among other processes.

“I think this application of electrokinetics could be a game changer,” says Armstrong.