The Southern Ontario Water Consortium (SOWC) is playing a critical role in pushing a Renfrew company’s latest innovation in wastewater treatment to market by removing the barriers that can arise in the final stages of development.

For many water technology companies, setting up a real-world demonstration that proves the effectiveness of a product to potential customers can be an uphill battle. But thanks to SOWC, Bishop Water Technologies now has a demonstration site, ministry approvals, a relevant research partner and the funding required to successfully demonstrate its innovative BioCord Reactor technology.

“Prior to connecting with the SOWC, we had already spent 18 months approaching municipalities to set up a demonstration site, but had not been successful,” says Kevin Bossy, CEO of Bishop Water Technologies. “The SOWC is the reason we are at this stage now.”

The company will be conducting a full-scale pilot demonstration project on its fixed film BioCord Reactor technology, which aims to improve the performance of active wastewater lagoons, at a test site in the Township of Southgate in Dundalk, Ontario.

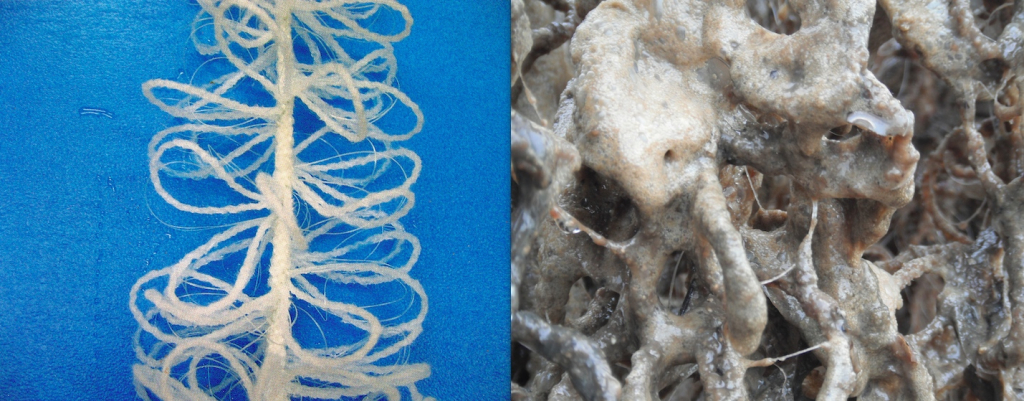

The BioCord Reactors are modules containing up to 1500 square meters each of looped cord that are installed directly into the wastewater lagoons. The cords work by maximizing the surface area that is available for existing bacteria in the water to latch onto.

“The bacteria that naturally breaks down the organic matter in wastewater lagoons is often just free floating,” says Bossy. “But when this bacteria can attach itself to something, it will grow in greater quantities, which means there is more bacteria to break down and remove the organics in the water.”

Having these modules means municipalities can easily upgrade the efficiency and capacity of their wastewater lagoons without costly infrastructure, adds Bossy.

Currently, there are a number of smaller municipalities across Canada with outdated lagoons that are no longer adequate because of increased development and recent, more stringent, changes to wastewater treatment standards.

“Municipalities are faced with having to add capacity as well as upgrade to modern standards,” says Bossy. “Instead of expanding their lagoons or building a costly mechanical plant, the BioCord Reactors are an easy and inexpensive solution that works with what they already have.”

However, before municipalities will buy into this new technology, they need to know that it works, which is why conducting a full-scale pilot demonstration in an active lagoon is so important to the commercialization process, adds Bossy.

“Having the SOWC with us at the discussion table with the municipality was extremely valuable because it helped the municipality view the demonstration as an opportunity to evaluate a potential solution rather than view it as just a sales pitch.”

BIoCord without (left) and with (right) biofilm. Copyright: Bishop Water Technologies

In addition to connecting Bishop Water Technologies with the municipality, SOWC also helped the company navigate through the provincial approval process.

“The SOWC made sure we were talking to the right people sooner than if we had tried it on our own.”

It also found the ideal researcher for Bishop Water Technologies to work with on the demonstration project. The SOWC has partnerships with 10 Ontario post-secondary institutions and their water experts so it was able to pinpoint which researchers would be best suited for the project and introduce the company to these researchers. In the end, the company selected Western engineering professor George Nakhla, who is also the SOWC wastewater node leader.

“The SOWC was able to bring us a few high-quality researchers who already had a passion for what we are doing and were prepared to come in and critique our product, which is what was important to us,” says Bossy. “It’s a tremendous opportunity to have someone as well-respected as George Nakhla working with us.”

Nakhla’s role in the demonstration project will be to collect and analyze data during the pilot demonstration and ultimately verify the effectiveness of the BioCord Reactors.

This will be the first project funded under the SOWC’s Advancing Water Technologies (AWT) Program, a program geared towards helping Ontario’s small to medium-sized enterprises leverage world-class research facilities and academic expertise to develop and demonstrate water technologies for successful introduction to the market.

The two-year project will look at the BioCord Reactors’ ability to maintain an active biomass in both summer and winter temperatures. Bacterial activity levels tend to drop during the colder months, which means there is a reduction in the breakdown of organics. So far the BioCord Reactors’ performance in cold temperatures has only been tested in the lab and in outdoor wastewater tanks.

The pilot demonstration will also help the company determine the most effective positioning of the BioCord Reactors in the lagoon. This will be achieved by taking regular water samples from different spots before and after the modules are put in.

The company has grown to 11 full-time employees in the past few years, up from three. This year, it reported revenue growth of 15% over last year. Bossy credits a supportive innovation ecosystem in Ontario, including assistance from the Water Technology Acceleration Project (WaterTAP). As a result of this full scale pilot, if successful, Bossy expects much more significant increases in revenue in the coming years.

“I am confident that by Spring 2017 we will be able to begin pushing towards providing this product to customers both in Canada as well as in areas across the globe where the BioCord Reactors can help reduce the expensive energy costs associated with mechanical treatment plants,” says Bossy. “When we start making sales and employing more people, our success will be attributed in part to SOWC.”

Other Coverage of the Project

Impact: Bishop Finds Nutrient Removal Success with Bacteria “Condos”