With support from the Ontario Water Consortium’s Water Industry Growth Program, USP Technologies Canada is refining their innovative “physical twin” model for sewer networks, aiming to optimize wastewater treatment processes and reduce greenhouse gas emissions.

Beneath city streets run hundreds of kilometres of sewers. It’s easy to think of them simply as pipes, moving sewage from source to treatment plant. But there’s lots of activity that occurs along the way, thanks to bacteria in the biofilm that naturally develops along sewer walls.

USP Technologies believes municipalities can leverage that bacterial action to reduce greenhouse gases, boost the productivity of wastewater treatment and cut energy use. And with help from OWC’s Water Industry Growth (WIG) program, they’re building the tools to make that happen.

Solving smelly problems

For years, USP Technologies has been helping municipalities solve the problem of hydrogen sulphide: a foul-smelling and corrosive sewer gas. By adding a combination of iron salts and hydrogen peroxide at strategic points in the sewer network, they can trigger reactions that break down or inhibit odours.

But determining when, where and how much to use within a sprawling sewer network was a challenge. “Sewers are so complex and big,” says Domenico Santoro, director of research and innovation at USP Technologies Canada — a subsidiary in London, Ontario that serves as the company’s research incubator.

Typically, assessing solutions means conducting full-scale tests at different sites throughout the system to see how they perform. But that’s an expensive approach that involves a lot of trial and error.

Creating tabletop twins

So USP Technologies Canada set out to design a scale model of a simplified sewer network — something that “perfectly emulate[s] the physics happening in a real sewer, but now in something you can put on your desk,” Santoro explains. As a result, users could finetune solutions before trying them in the field.

Creating the model wasn’t simple. That’s because changing the length or diameter of pipes affects things like flow behaviour and settling. Plus, an accurate model had to incorporate the microbial action that happens in real sewers.

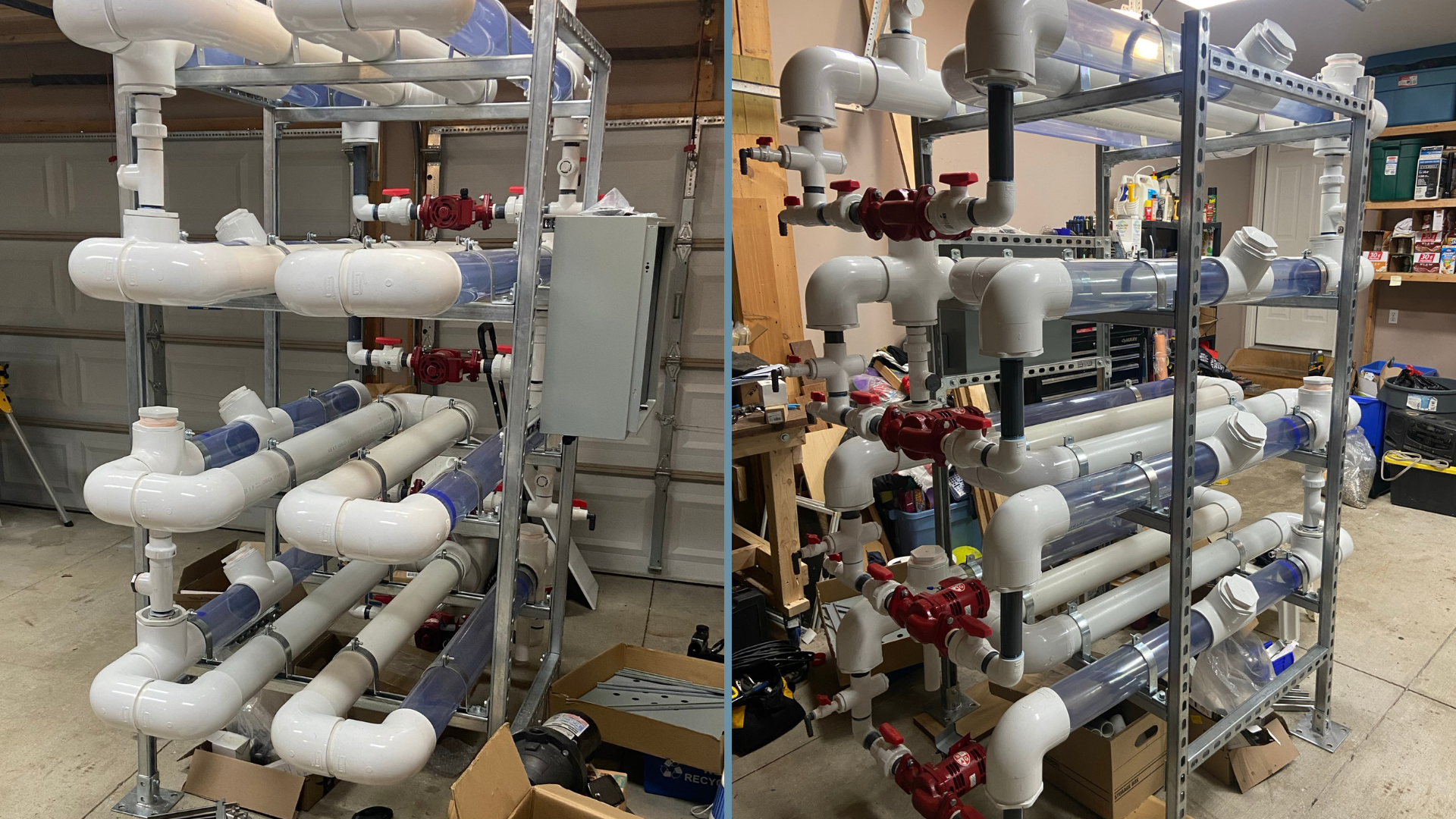

But Santoro’s team persevered. Today, their “physical twin” consists of multiple pipes connected with pumps and valves to replicate real-world flow patterns. And because it allows researchers to independently control different parameters like flow rates and residence, they can understand the impact that different interventions create.

On top of that, Santoro and his team succeeded in replicating biofilm — a big breakthrough that allows their system to accurately model the biochemistry going on in sewers.

Tackling GHG emissions and optimizing operations

Now, with funding from WIG, Santoro is adapting their physical twin to help tackle more than just odours. For example, sewers also produce potent greenhouse gases like methane and nitrous oxide, making them prime targets as cities get serious about cutting their carbon footprints.

Everything from pH levels to temperature to how long sewage sits in a pipe can influence the production of planet-warming pollutants. And USP Technologies Canada’s physical twin can help cities zero in on ways to optimize these different factors to reduce emissions — whether it’s by tweaking sewer designs, adding chemicals or adjusting maintenance regimens.

Similarly, researchers can use the model to figure out the best conditions to encourage bacterial action in the sewer. The more those bacteria can break down organic material before sewage arrives at the treatment plant, the less work the treatment plant would have to do.

Essentially, the sewer system could serve as a vast pre-treatment stage, cutting the plant’s energy use and operational costs. It would also allow cities that are tight on space to expand their treatment capacity without increasing the footprint of their facilities.

Creating models that do more

With support from the WIG program — which helps commercialize game-changing innovations in the water sector — USP Technologies Canada is now testing and refining early prototypes of their models.

That support has been crucial, according to Santoro. Not only has it sped up their progress, it also makes it easier for the company to attract more investments. “It’s been very valuable,” says Santoro. “For us it’s all about acceleration.”

By the end of 2024, he expects to have a completed system that will help customers quickly and accurately identify the best sewer solution.

Meanwhile, WIG funding is helping another company — Dynamita North America — build a complementary digital model of sewer networks. The software firm is creating AI-powered influent predictors, programs that simulate greenhouse gas emissions and more, creating even more insights into sewer performance.

Ultimately, Santoro would love to develop one more tool: a physical treatment plant twin that connects to the physical sewer twin. Creating a complete model of wastewater infrastructure would break down the current barriers between sewer managers and treatment plant managers, allowing them to view the system as a whole.

“What you do in the sewer has implications in the plant,” he says. “The vision we have is that they are totally connected.”

WIG supports industry innovations that accelerate growth, create jobs and strengthen Ontario’s water sector. For more information, click here.