With support from the Ontario Water Consortium’s Water Industry Growth Program, Digital Water Solutions is reshaping water distribution network management with their groundbreaking hydrant.AI technology.

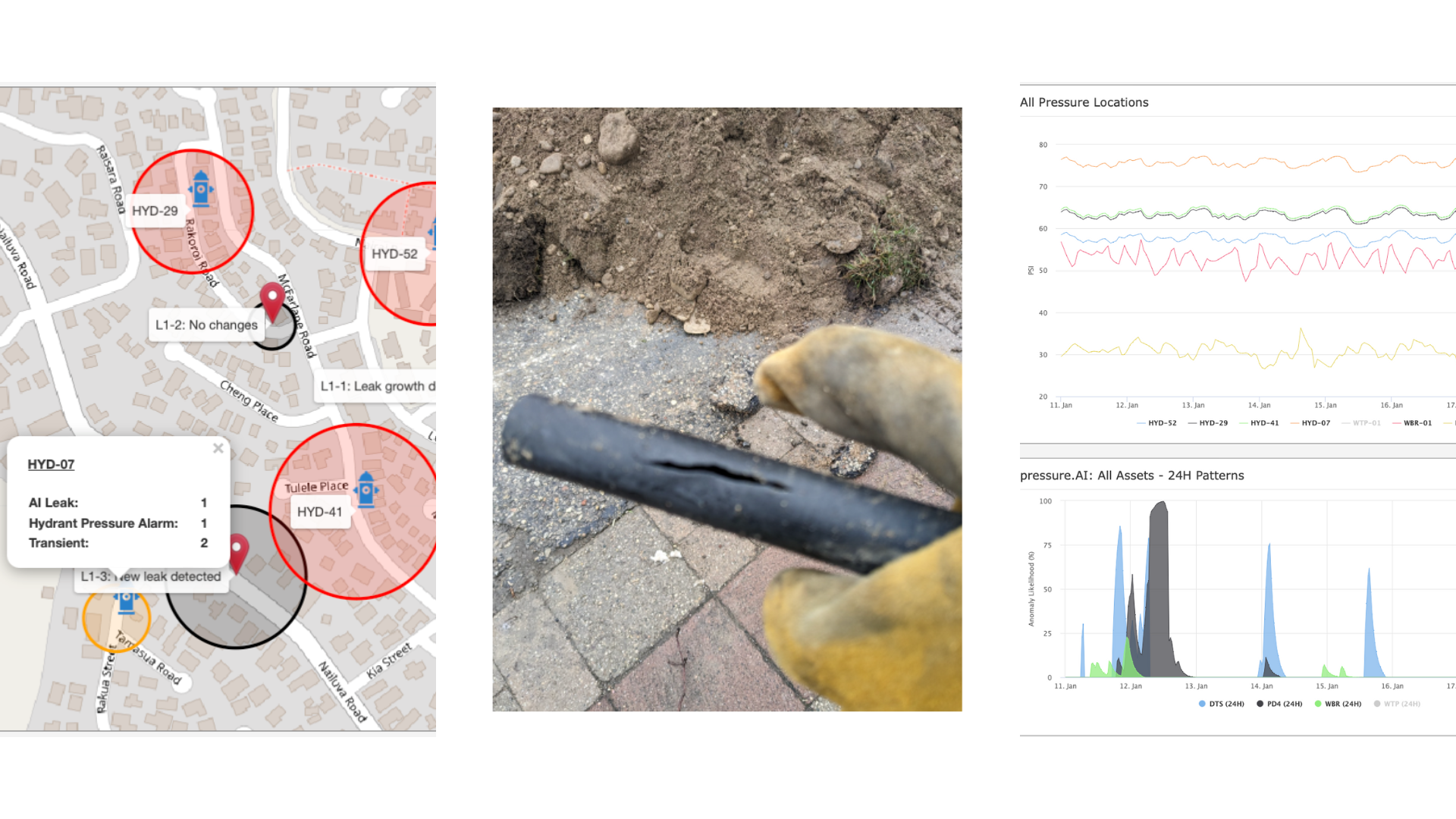

Today, many communities lose up to half of the drinking water they treat due to leaks in their distribution networks. To help tackle the problem, Digital Water Solutions (DWS) developed ground-breaking technology with support from OWC. Their hydrant.AI devices sit inside fire hydrants, gathering acoustic, pressure and temperature data from within the water column. Then, AI software gets to work, using that data to identify and localize low-level leaks — and even predict catastrophic bursts before they occur.

The more devices a utility can install across a distribution system, the easier that becomes. But that drives up the costs. Plus, there are other parameters of the network — such as water consumption, flow rates and water quality — that the DWS sensors cannot monitor.

So to make their solution even more robust, the Guelph company is now exploring ways to combine their acoustic signals with data from other sources, such as water meters and flow sensors.

Those devices are already collecting information that could help detect the presence of leaks. But too often the data languishes in disconnected siloes, says Stan Fong, Chief Technology Officer at DWS.

“We can take all those sensors and basically fill in the blanks,” he explains. “Does the pressure also indicate that there may be a leak? Do I see increased flows? Am I seeing chlorine residuals go up or down? … Imagine if you could make a decision with all of that information.”

By integrating additional sources into their AI platform, DWS aims to give utilities richer real-time insights and broader monitoring coverage across their distribution networks.

Making smart monitoring even smarter

Since August 2023, DWS has been conducting tests to assess whether the basic concept could work. So far, all signs point to yes. Now, they’re expanding to a wider variety of real-world data sets.

But combining information from multiple sources is just part of the challenge. The technology also needs to make sense of it all. To do that, Fong and his team are developing an AI-powered decision support platform, which can analyze any data source and transform it into actionable insights.

That could include alerting operators to low-level leaks. Or identifying areas for repairs and replacement before they catastrophically fail.

At the same time, DWS is redesigning the user interface to accommodate these new features and make it as intuitive as possible. Finally, they are working to miniaturize their existing hydrant.AI hardware, making it small enough to fit anywhere in the distribution network — not just in the relatively roomy headspace of a fire hydrant.

To bring their ambitious vision to life, DWS turned to OWC’s Water Industry Growth (WIG) program, which helps companies across the province commercialize innovative water technologies. Fong calls that funding “super important,” allowing the company to hire on another full-time employee and, in his words, “shoot for the moon.”

“Without projects like this, we wouldn’t be able to do it,” he says.

Tackling a costly problem

Fong knows how valuable real-time leak monitoring can be. DWS recently wrapped up a study with the Region of Waterloo, which began with the local utility using traditional approaches to find and repair underground leaks.

Once they were done, DWS installed their hydrant.AI devices, which revealed low-level leaks that had gone unnoticed. “One of them was basically the flow rate of a shower head,” Fong says.

Small though it was, that leak alone cost the Region nearly four million litres of water in just two months, representing more than $10,000 in revenue — not to mention greenhouse gas emissions. Fong estimates you’d need to plant six trees every month to offset the CO2 used to treat and distribute that wasted water. In some parts of drought-stricken California, he points out, a utility that fails to fix those kinds of leak could face heavy fines and regulatory pressure.

Meeting a growing need for solutions

By the time the WIG-funded project wraps up in March 2024, Fong expects to have an even more powerful real-time monitoring solution available for utilities. And not a moment too soon, as the need for smarter monitoring continues to grow.

Throughout North America, pipes laid in the ’60s and ’70s are becoming weakened or corroded. A large proportion of the utilities workforce is retiring, taking decades of leak-detection expertise with them. And the shift to plastic and PVC pipes is making leaks harder to detect, since they don’t transmit sounds as effectively as traditional metal pipes.

Meanwhile, as climate change accelerates, the stakes keep increasing — especially in places dealing with water scarcity issues like California and the American Midwest. “But it’s a big problem everywhere,” says Fong. “You really can’t afford to have these leaks.”

Thanks to DWS, utilities will soon be better equipped to take action: finding and fixing leaky pipes quickly, preventing catastrophic bursts and making every drop count.

WIG supports industry innovations that accelerate growth, create jobs and strengthen Ontario’s water sector. For more information, click here.